Solvent Based Zircon Coating

Solvent Based Zircon Coating Specification

- Purity

- 65%

- HS Code

- 38241000

- Ph Level

- 5

- Taste

- Other

- Boiling point

- 800

- Smell

- Sharp

- Density

- 1.10 Gram per cubic centimeter(g/cm3)

- Form

- Liquid

- Solubility

- Solvent

- Storage

- Room Temperature

- Grade

- Industrial Grade

- Type

- 1002 MF MOL GS

- Usage

- Solvent-based zircon-rich coating for superior thermal resistance, anti-penetration, and smooth surface finish in foundry molds and cores.

- Main Material

- Graphite

Solvent Based Zircon Coating Trade Information

- Minimum Order Quantity

- 1000 Kilograms

- FOB Port

- MUNDRA

- Supply Ability

- 50000 Kilograms Per Month

- Delivery Time

- 1 Week

- Sample Available

- No

- Sample Policy

- Free samples are available

- Packaging Details

- 50 KG DRAM

- Main Domestic Market

- All India

- Certifications

- ISO 9001

About Solvent Based Zircon Coating

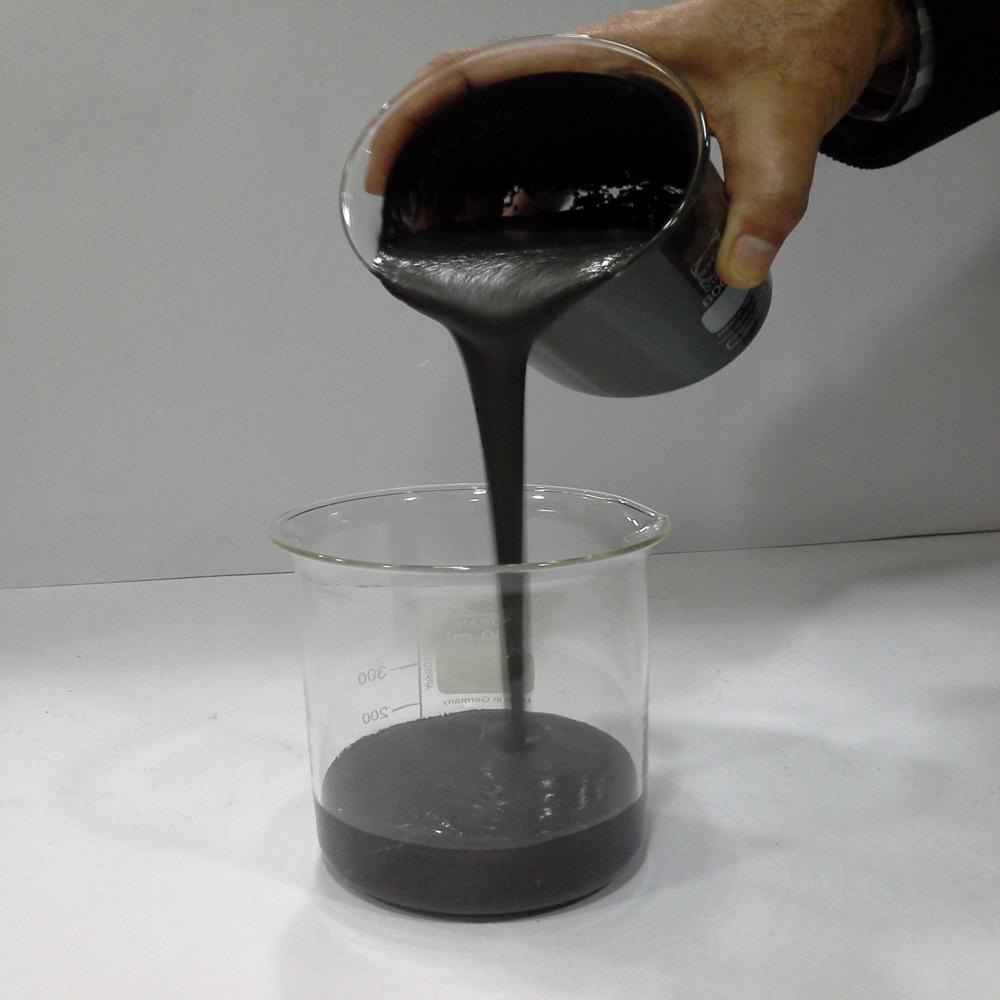

Mitra Fusion India Pvt. Ltd. presents Solvent-Based Zircon Coating, specially formulated for high-performance mold and core surface coating in foundry applications. Enriched with premium zircon, this coating offers exceptional refractoriness, thermal shock resistance, and a smooth casting surface finish. It effectively prevents metal penetration and sand fusion, making it ideal for critical and high-temperature casting operations. Suitable for application by brushing, dipping, or spraying.

Exceptional Thermal Resistance and Surface Quality

Solvent Based Zircon Coating is engineered to withstand extreme temperatures, making it ideal for foundry molds and cores. Its zircon-rich formula and graphite ingredient ensure minimal penetration from molten metals and deliver a smooth finish. This improves the durability and performance of molds during casting operations, reducing defects and enhancing output quality.

Industrial Grade Performance

Formulated for demanding industrial applications, this coating meets stringent standards for purity and efficiency. The liquid form allows for easy, effective application on various mold surfaces, ensuring consistent coverage and protection. With a pH level of 5 and a boiling point of 800C, it addresses the needs of professionals seeking superior results in casting environments.

FAQs of Solvent Based Zircon Coating:

Q: How should Solvent Based Zircon Coating be applied to foundry molds and cores?

A: Apply the coating evenly using brush, spray, or dip methods as suitable for your mold or core. Ensure the surface is clean and dry before application for optimal adhesion and performance.Q: What are the key benefits of using this zircon-rich coating in foundry operations?

A: It provides excellent thermal resistance, minimizes penetration by molten metals, and creates a smooth surface, thereby reducing casting defects and increasing mold longevity.Q: When is the ideal time to use this coating during the manufacturing process?

A: The coating is typically applied after mold or core preparation, before casting. It acts as a protective barrier to enhance mold performance during each casting cycle.Q: Where can this coating be stored for best results?

A: Store the product at room temperature in a well-ventilated area, away from direct sunlight or sources of ignition, ensuring the integrity and effectiveness of the liquid coating.Q: What is the process for preparing molds before applying the coating?

A: Clean and dry the mold or core surface thoroughly to remove any residues. This preparation allows the solvent-based coating to adhere properly and achieve full protective properties.Q: How does the sharp smell and pH level affect handling and safety?

A: The sharp smell is characteristic of its solvent base and graphite content; proper ventilation is advised during use. The pH level of 5 suggests mild acidity, so using gloves and avoiding skin contact are recommended safety measures.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in FOUNDRY CORE & MOLD COATING Category

1007 MF COAT ASW ( Alumina-Silicate Water Base Coating)

Price 42.0 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Type : Liquid

Purity : 60/40

Storage : Room Temperature

Form : Powder

FOUNDRY COATING

Price 38.0 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Type : Paste

Purity : 60%

Storage : Room Temperature

Form : Other

1006 MF COAT ZW (ZIRCON + WATER BASE COATING)

Price 190.0 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Type : 1006 MF COAT ZW (ZIRCON + WATER BASE COATING)

Purity : 96% 99%

Storage : Room Temperature

Form : Liquid

COAT-GW (Graphite Water Base Coating)

Price 60.0 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Type : COATGW (Graphite Water Base Coating)

Purity : 99%

Storage : Room Temperature

Form : Liquid